1. Enhanced Energy Efficiency

One of the standout features of MDR technology is its ability to operate efficiently. In traditional belt-driven systems, the belt runs constantly, consuming energy even when it’s not actively transporting items. Energy-efficient conveyor systems, like MDR spiral conveyors, only activate the rollers when an item is detected. This on-demand activation reduces the amount of energy consumed, resulting in significant cost savings over time.

Unlike conventional conveyors, where the entire system runs continuously, an MDR spiral system only uses energy when the conveyor operates, making it a perfect choice for high-throughput environments where energy savings matter.

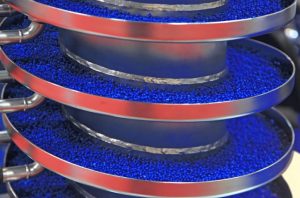

2. Space Optimization

Space is always at a premium in warehouses and manufacturing facilities. MDR spiral conveyors take advantage of vertical space, allowing you to move products up or down without eating up valuable floor area. Instead of sprawling horizontally, these systems operate in a compact spiral, making them an excellent solution for tight spaces where traditional conveyors might not fit.

With MDR spirals, you’re essentially freeing up space for other activities or storage, which can help you improve your overall facility layout and productivity.

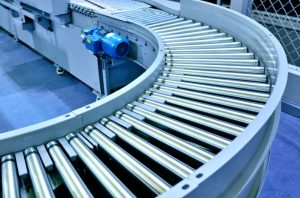

3. Reduced Noise and Maintenance

Another advantage of MDR systems is that they’re quieter than traditional belt-driven conveyors. The rollers work smoothly and efficiently, generating less noise, which leads to a more comfortable and less distracting work environment.

Additionally, MDR systems have fewer moving parts than belt conveyors. There’s no long, cumbersome belt to wear out, no motors constantly running, and no tensioning devices that need constant attention. This means less wear and tear, fewer breakdowns, and reduced maintenance costs over time.

4. Precise Control

When it comes to moving products, particularly delicate or irregularly shaped ones, precision is key. MDR spiral conveyors provide just that. The motor-driven rollers allow for smoother, more controlled movement, ensuring that your items stay in place as they travel up or down. This precision is especially useful when handling fragile or lightweight items that may be at risk of tipping or being damaged in other systems.

5. Scalability and Flexibility

One of the most exciting features of MDR spiral conveyors is their modular design. This means they can be easily adapted, expanded, or reconfigured to fit your facility’s ever-changing needs. As your business grows, you can add more levels or adjust the system’s layout to suit new products or increased throughput.

This flexibility makes MDR spirals a smart long-term investment for any operation that anticipates growth.