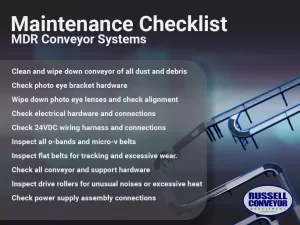

Regular maintenance ensures your conveyor system’s reliability and smooth operation. Regular inspections and maintenance help prevent unexpected breakdowns or failures by identifying and addressing potential issues.

One key area that requires attention during maintenance is the conveyor controls. These controls include various components, such as belts, motors, and bearings, which are vital to the system’s overall functioning. Regularly inspecting and maintaining these controls is essential to prevent any malfunctions or failures that could disrupt the conveyor system’s operation.

Inspecting the conveyor belts is an important part of maintenance. Over time, belts can become worn out, damaged, or misaligned, which can lead to inefficiencies or even complete breakdowns. By regularly inspecting the belts, you can identify any signs of wear and tear, such as fraying, cracking, or stretching. Additionally, checking for proper alignment and tension ensures the belts run smoothly and efficiently.

The motors powering the conveyor system also require regular maintenance. These motors are responsible for driving the belts and ensuring the smooth movement of materials. Checking motors often for wear, overheating, or strange noises can cause problems before they cause a breakdown.

Additionally, it is necessary to oil the motor bearings. All bearings must be aligned properly. It is also crucial to check that the bearings are working well. By doing these tasks, you can achieve long-lasting and efficient performance.

Bearings are another critical component of conveyor controls that require regular maintenance. These bearings support the rotating parts of the conveyor system, such as pulleys and rollers, and help reduce friction. Over time, bearings can become worn out or damaged, leading to increased friction, heat generation, and potential failures. Regularly inspecting and lubricating the bearings can help prevent these issues and ensure smooth operation.

In addition to inspecting and maintaining specific components, regular maintenance also involves general cleaning and upkeep of the conveyor system. Removing any debris, dust, or buildup from the belts, motors, and bearings helps prevent blockages, reduces wear and tear, and improves overall efficiency.

By prioritizing regular maintenance and inspections of conveyor controls, you can minimize the risk of unexpected breakdowns, extend the lifespan of your system, and ensure its reliable operation. This proactive approach saves time and money and helps maintain a safe working environment for your employees.