History of the components behind the Live Roller Conveyor

Serious arguments could be made about the history of Live Roller Conveyor. We can trace varying patents back 75-100 years; however, we would argue that the principles of Conveyor rollers date back even further than that.

How far back? All the way back to the invention of the wheel. We know that the “Live” part of Live Roller Conveyor means “powered” and not gravity, but just bear with us for a moment. For as long as civilizations have had access to round objects, they have used those objects to move heavy items.

According to National Geographic, “We forget that ancient people are just as smart as we are,” said Terry Hunt, an archaeologist at the University of Oregon who studies the Polynesian culture of Easter Island. “In fact, they may have been better focused because they didn’t have our distractions.”

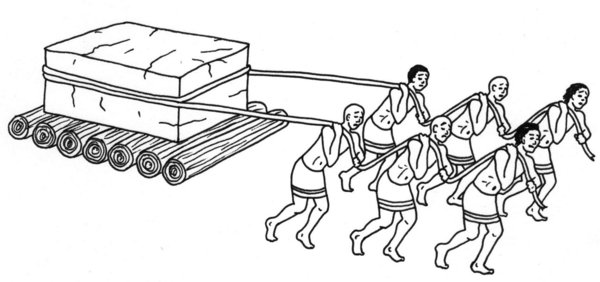

Some have even taken four round objects, attached them to a steel body, and called it an automobile. A winning concept, huh? In all seriousness, very rarely does one see old photos or drawings (we mean old photos) of people moving heavy items with anything other than round objects. Early settlers in our nation used logs to move everything as they did not have access to tractors or powered equipment.

Small logs were used to move larger logs with which they built their homes and structures. Studies have shown how ancient civilizations moved large stones and monuments such as the 13-ton stone monuments of Easter Island.

What was the conclusion? How did they accomplish that? Round objects! So next time you look at pyramids in Egypt, think about how they moved those large stones and know that some form of Live Roller Conveyor principles probably had something to do with them being able to accomplish that monumental feat.

For as long as civilizations have had access to round objects, they have used those objects to move heavy items