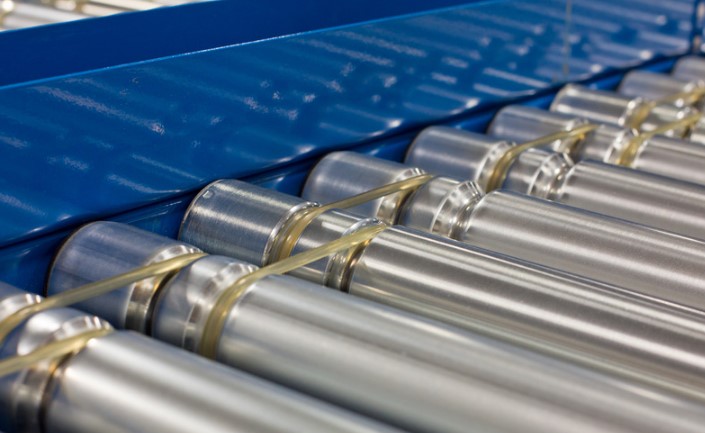

When RF picking solutions and conveyor systems are integrated, the result is a highly efficient order fulfillment process that combines the strengths of both technologies. Here’s a closer look at how this dynamic duo works together to optimize warehouse operations:

Streamlined Picking Process: RF picking solutions direct workers to the exact location of an item, eliminating guesswork and reducing the time spent searching for products. Once the item is picked and scanned using a barcode scan, it can be placed directly onto a conveyor system. The conveyor then transports the item to the next stage of the process, such as packing or shipping. This seamless integration reduces manual transportation, saving time and labor while minimizing the risk of errors. Additionally, integrating RF picking with pick to light systems can further enhance the picking efficiency by visually guiding workers to the correct locations.

Real-Time Inventory Management: As items are picked and placed onto conveyors, RF systems update inventory levels in real-time. This continuous flow of accurate data ensures that stock levels are always current, reducing the risk of stockouts or overstocking. With real-time visibility into inventory through advanced inventory management systems, businesses can make more informed decisions and maintain optimal stock levels. This integration of RF picking with inventory control helps streamline inventory management processes and improves overall order fulfillment efficiency.

Reduced Order Fulfillment Times: The combination of rapid, accurate picking with automated conveyor transportation significantly cuts down on order fulfillment times. By speeding up the movement of picked items through the warehouse, businesses can dispatch orders more quickly and improve overall customer satisfaction. Faster order processing, facilitated by various types of warehouse automation, also means that warehouses can handle higher volumes of orders without compromising on accuracy.

Enhanced Accuracy and Quality Control: RF picking solutions help minimize picking errors by guiding workers through the picking process and confirming item selections with barcode scanning. When combined with conveyors, the accuracy of the process is further enhanced. Automated transportation reduces the likelihood of items being misplaced or handled incorrectly, leading to higher accuracy in order fulfillment and a reduction in costly returns. The integration of RF picking with pick to light systems and other types of warehouse automation ensures that both accuracy and quality control are significantly improved.

Optimizing Workflow and Layout: The integration of conveyors with RF picking solutions allows for a more efficient workflow and optimized facility layout. By strategically placing conveyors, warehouses can create a continuous flow of goods from picking to packing and shipping. This approach reduces bottlenecks, streamlines operations, and ensures a smoother overall process.

Additionally, conveyors can be installed in overhead or narrow spaces where manual handling would be challenging. This flexibility in placement allows for better space utilization and contributes to a more organized and efficient warehouse layout.

0 Comments